Corrugated metal roofing and its close cousin, ribbed panel roofing, offer the original style of corrugated (iron) steel roofs. At an average cost of $5.50 to $8.50 per square foot installed, corrugated metal is priced somewhat similarly to asphalt shingles, especially at the low end, and yet, high-end corrugated metal panels are far more durable, energy efficient, and can last far longer than asphalt shingles.

Asphalt Shingles

Asphalt Shingles

$8,500 Average Cost |

Metal Roof

Metal Roof

$15,500 Average Cost |

Flat Roof Membrane

Flat Roof Membrane

$11,500 Average Cost |

|

|

||

What Exactly Is Corrugated and Ribbed Metal Paneling?

Sheet metal coil (typically galvanized steel or aluminum) gets fed into a roll-forming machine that shapes the metal sheet into the curvy U-shaped, wavy pattern — the primary variation for corrugated metal roof and wall panels.

Corrugation gives metal panels considerable structural strength, which makes it possible to use these otherwise thin sheet metal panels for building envelope applications, such as roofing and cladding.

Check out the video below to see how it’s made:

Old School Corrugated Steel Panels

During the height of the Industrial Age, steel became relatively cheap and abundant. Metal was viewed as the kind of material that offers an economically viable way to cover the roofs on large agricultural and industrial buildings. Back then, the corrugated steel panels were often non-coated, but that was not a problem since there were plenty of spare steel roofing and wall panels to replace any corroded ones as needed.

As steel corrodes, it develops visible rust. When the old steel panels would get too unsightly or worse yet, develop holes resulting in leaks, they would get replaced with the shiny new pieces.

Today, corrugated metal panels are often chosen because of their old school appearance and relatively low cost compared to standing seam and architectural metal shingles and tiles.

Most modern corrugated steel panels are normally coated with a galvanic (zinc) self-healing zinc coating to prevent oxidation and corrosion, and thus made to last for decades, especially when finished with a high-end Kynar 500 factory applied paint finish.

G-60 vs. G-90 Galvanized Steel Panels and their Paint Finishes

Steel panel coating process is referred to as galvanizing. There are two types of galvanized steel panels: G-60 and G-90 steel panels. G-60 refers to the low-end, lower quality and lower cost galvanized steel, while G-90 is the higher-end, thicker and longer lasting grade of galvanized steel.

G-90 steel panels are also normally finished with a higher-end paint finish such as Kynar 500 as opposed to the cheaper acrylic paints normally used for the low-end G-60 steel panels.

Note: G-90 (26-gauge, 24-gauge, and 22-gauge) steel panels finished with Kynar 500 paint can be used in residential applications, while G-60 (29 gauge) steel panels with polyester or acrylic paint should only be used for sheds, garages, and/or on lower-end/low-priority agricultural and commercial/industrial applications.

Corrugated Metal Panels vs. Crimped or Ribbed Metal Roofs

Corrugated metal panels are not the same as crimped or ribbed metal panel. Corrugated metal refers strictly to the U-shaped, or sometimes V-shaped panel sheets.

The rustic appearance of corrugated metal panels hearkens to the simpler time, or way of life. However, the main benefits of corrugated metal panels are their cost-effectiveness, durability, and a wide range of available colors and paint finishes.

Installation and Options

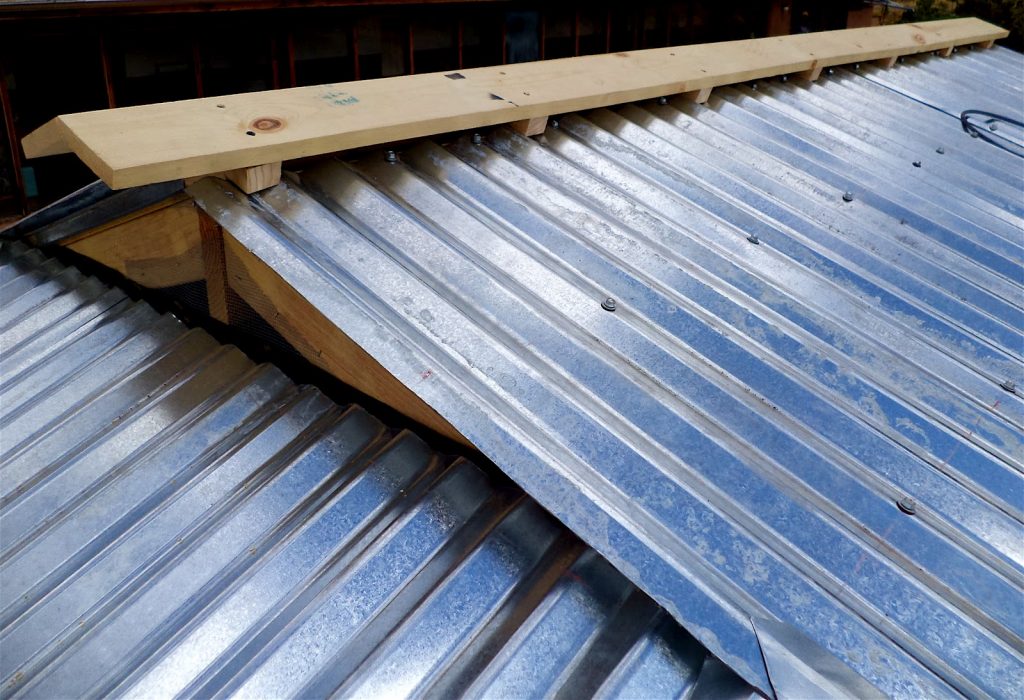

Corrugated metal panels tend to be between 2 and 3 feet wide and come in varying lengths such as 8 ft. and 12 ft. long metal panel sheets. When covering a roof, metal panels form overlaps along their curves. The panels are then fastened together with metal screws that penetrate not just the two panels, but into the roofing deck or substrate.

Obviously, the metal panels themselves will shed water, given the proper slope of the roof, as metal is not a porous material. Yet, with the panel overlaps, a seam is formed and to prevent water leaking into or through that tiny gap, caulk is used.

Covering the entire roof with corrugated metal panels can go rather quickly, especially on a simple gable roof, once the installer has all the necessary tools, experience, and help from others.

Both corrugated and ribbed metal panels can make for a fairly simple DIY roofing project when covering a small shed or garage, as explained in this guide from DoItYourself.com.

However, the installation process can be quite grueling and tedious on larger projects, especially for the less experienced, which is why larger projects would almost always benefit from getting a professional installation, like all roofing projects.

And since the cost is not too high, it would be best to go with the insured and certified professionals, providing warranties on their products and workmanship.

When it comes to options, it’s really about the actual material and its thickness or gauge, paint finish and the color options. Steel is still the primary material option.

In today’s world it is routinely coated or labeled as galvanized steel. Sometimes, you’ll see it as Galvalume steel (zinc and aluminum metallic finish). — Both coating options offer a layer of protection that will take a decade or two to sacrifice themselves before the steel is exposed. Thus, premature rusting is no longer a problem for at least 20 years from the time the roof is installed.

Aluminum is another metal option for corrugated panels. The costs are virtually the same as (coated) steel. Stainless steel (which is an alloy of steel and chromium) is also an option, but stainless steel is more expensive.

Stainless steel corrugated panels are highly corrosive resistant and will provide a shinier appearance than normal steel products.

Typically, the products are sold in a 26-gauge, 24-gauge, and 29-gauge steel. The smaller the gauge number, the thicker and stronger the metal panel is. And the thicker the material, the more durable and long lasting the metal panels will be. Though panel thickness does add a little more to the labor intensity and quite a bit to the material costs.

Note: You should aim for a minimum of 26-gauge G-90 steel panels finished with Kynar 500 paint when evaluating residential steel roofing options. Lower/thicker gauge steel like 24-ga and 22-ga steel panels will also work great and provide enhanced performance in terms of durability and longevity of a metal roof.

Color options are virtually unlimited with custom colors. With standard colors, there will normally be 10 to 30 colors to choose from, depending on the system manufacturer. — This references the painted metal roof finishes. The DIY approach to painting such metal panels is there, but it is likely way more expensive than going with a factory finish.

The factory process feeds metal panels through the metal mill and coats it evenly in short order. Using superior paint pigments, it also shields the product with yet another layer of supreme protection.

If going with a professional contractor, they’ll probably have brochures of different color options that they carry (usually 10 to 40 options). Customized color options are also available, but usually at a premium cost (like $0.25 to $0.75 extra per square foot), as they aren’t massively produced.

Your local home improvement store, like Lowe’s or Home Depot, probably carries such panels. These will be inexpensive, though size and for sure color options will be limited.

Keep in Mind that corrugated metal panels aren’t just for roofs. Chances are good that your roofer will have some left-over material (unless otherwise noted in the contract or specifically discussed) that you might find use for as siding in an exterior shed, or even in interior projects. Take a gander at the picture below for some ideas on how the panels can be used indoors.

via Bridger Steel

via Bridger Steel

Cost and Value of Corrugated Metal Roofing

Materials:

High-end — Residential Grade Metal Panels: 26-guage and 24-gauge, G-90 corrugated steel panels finished with Kynar 500 paint, will cost between $1.50 – $2.50 per square foot, depending on the thickness of the panels, specific metal roof profile like corrugated R-panel/ribbed and the amount of metal used per panel, and whether the paint finish color is standard or custom.

Low-end — Non-Residential Panels corrugated and ribbed panels like the 26-gauge unpainted G-90 galvanized or Galvalume steel, and/or the thinner 29-gauge G-60 steel panels, and/or 26-gauge G-90 steel panels finished with lower-end polyester paint, will typically cost between $1.00 and $1.50 per square foot.

Cost Installed:

Corrugated panels are the least expensive metal roofing option, while Standing Seam is by far the most expensive option. With corrugated metal roofing, pricing starts in the $5.50 to $7.50 per sq. ft. installed range. — That’s for a full installation of a basic G-60 galvanized steel (29-gauge) or G-90 galvanized steel (26-gauge), painted (with acrylic or polyester, non-Kynar 500 paint finishes) panels, charged by the square foot.

Note that 29-gauge G-60 corrugated steel panels are too thin and light for the true residential-grade roofing applications. It’s OK to use G-60 corrugated or ribbed panels for low-priority applications like sheds.

The G-60 refers to amount of galvanic (zinc coating) coating per sq.ft. While G-60 steel is the low-cost option compared to G-90 steel, it is still much higher quality than our ancestors went with 150 years ago.

If you want to get a solid, residential-grade mid-range corrugated or ribbed metal paneling option for your home, then go with a system like G-90 galvanized steel, 26-gauge/24-gauge, with factory finished Kynar 500 paint (not polyester or basic acrylic paint), then the range is around $5.50 to $8.50 per sq. ft. fully installed. — Such a system can achieve 30 to 40 years of service lifespan, which double of what you can expect from an asphalt shingle roof.

The reason for the larger range on the second option is the variability in all the other important factors that would be considered, such as quality and color of the metal panels, quality of the installer, your home’s location, complexity of your roof, along with how steep the slopes are, and whether the existing roof needs to be torn off or not.

Even at $6.50 to $8.50 per sq. ft. installed, the high-end R-panel or ribbed metal roofing with either exposed or concealed (more-costly) fasteners, is still far less expensive than standing seam.

Although, standing seam does have an important benefit of having hidden or concealed fasteners, and hence far less chances of leaks in the first 30 years.

Metal

Flat

$15,500

$11,500

Did you know? Corrugated steel roofing panels generally contain over 30% of recycled steel, which qualifies the product for LEED credit awarded by the green building council.

Metal roofs have an excellent ROI, or the value you can expect to get for your corrugated metal roof at time of selling your home. The national average cost recouped is about 86% of what you initially put in.

Advantages of Corrugated Metal Roofing

- Relatively low cost compared to standing seam and metal tiles, both for materials and installation

- Being metal, it is fire resistant, and moss growth along with bugs and rodents will not be a problem

- Multiple premium color options available including custom colors in Kynar 500 paint finish

- Great ROI

- Eco-friendly and Energy-efficient

Disadvantages of Corrugated Metal Roofing

- Not as leak proof as standing seam or metal shingles due to exposed fasteners

- Generally needs maintenance after 15-20 years, such as inspecting and re-tightening fasteners, re-caulking if necessary

- Aesthetically, not the most beautiful of metal roofing options, though it is a subjective consideration

Need a Pro? Check out Prices from Local Roofers:

Enter your zip code:

See what local pros charge

See what local pros charge

The two quotes for putting some aluminum or steel corrugated roofing over an existing sun room roof were $3,000 and $3,000+. I had checked out the roofing prices on line before getting the estimates. I feel the two contractors were trying to rip me off, either because I am female, a senior citizen… or because they want to make a killing on their jobs because of the stimulus $ they know we have received. What should the installed roofing price be, approximately?

Hi Kristine,

It’s difficult to tell whether the quotes are fair without knowing the type of corrugated metal panels quoted.

Were the prices quoted for G-90 galvanized steel panels (24 or 26 gauge thick) with Kynar 500 paint finish? Or were the quotes for a lesser-grade steel panels like the G-60 (29-gauge) galvanized steel with polyester paint finish?

You should only install G-90 steel panels (26 gauge or 24 gauge) with Kynar 500 paint finish on a house (assuming sunroom is part of the house).

We also need to know a little bit about the roof including the size, slope, whether the tear off is needed. Lastly we need to know where you are located. Without knowing the size of the roof and project specifics, it’s difficult to weigh in on the fairness of the quote.

We can estimate that the existing sunroom probably has somewhere between 150 and 300 square feet of roof coverage, depending on the size of the sunroom and roof slope. We also assume the roof has a sufficiently steep slope like 4/12 or greater to allow for the installation of a corrugated or ribbed metal roof.

If the roof size spans 300 square feet or 3 squares, then you are being quoted $1,000 per square to install corrugated metal panels. Where are you located? Maybe you should also get some quotes for a standing seam roof for comparison.

Make sure you are also getting a workmanship warranty on the job. The current price surely seems a bit high, but it’s tough to tell without knowing the specifics. Also note that smaller jobs will typically have high set up costs including building permits, job-site prep, standing behind the warranty, etc.

For a larger-sized job, the price per square (10 x 10 square feet area) should be considerably lower when going with corrugated steel panels. The location of the property and local real estate values also play a major role in the overall price of the job.