Standing seam is the premier choice in residential metal roofing. It is also the most expensive; around two or three times the cost of corrugated metal panels and asphalt shingles, and about 10% to 20% more than metal shingles like interlocking steel and aluminum tiles and shakes.

Standing seam offers unbeatable value (through durability, longevity, energy-efficiency, and style) that is hard for any other roofing material to match. Let’s explore this in further detail:

Cost

The current national average cost to install a standing seam metal roof on a typical single-family house can range between $12.50 and $20.50 per square foot or $1,250 and $2,050 per square. This assumes a professional and warrantied installation of G-90 galvanized steel or Galvalume 26-gauge or 24-gauge (better) steel panels finished with the factory applied Kynar 500 paint finish. Aluminum panels finished with Kynar 500 paint are also an option and may cost slightly more than steel.

Asphalt Shingles

Asphalt Shingles

$8,500 Average Cost |

Metal Roof

Metal Roof

$15,500 Average Cost |

Flat Roof Membrane

Flat Roof Membrane

$11,500 Average Cost |

|

|

||

When estimating the total cost of a project: For a typical 2,000 square foot roof, it will cost between $25,000 and $41,000 for a complete installation including all the materials and supplies, professional application, product and workmanship warranty, and any necessary building permits for the job. Removal and disposal of the old roof may be extra, depending on the extent of additional work required to complete the job.

G-90 Galvanized Steel is the most popular or most-often used option for residential standing seam roofs. The “G” here refers to the amount of the zinc plating, as in .90oz per square foot.

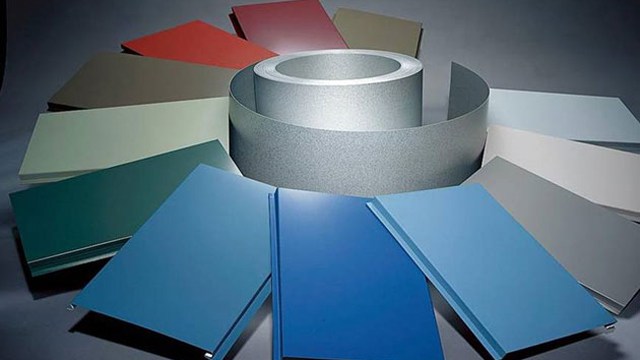

Did you know? Standing Seam is also available in Aluminum, Galvalume, G-90 galvanized Steel, Zinc, Copper, and Stainless Steel.

While technically, aluminum is more expensive than steel, the reality is the costs aren’t noticeably different when considering the ultimate cost of a new metal roof to homeowners when installed by professionally trained metal roofing contractors.

If the materials were not coated and not finished with the high-end factory paint finish like Kynar 500, then perhaps the higher cost of aluminum would be something of note. In the current market, they are virtually the same cost.

Cost of Materials and Important Nuances on Pre-Cut vs. Custom-Fabricated Metal Panels

Standing seam metal panels and trim will cost between $4.50 and $7.50 per sq. ft. for made-to-order or custom fabricated metal panels, depending on the profile and color, overall order size, project location, and contractor’s supplier relationship.

In terms of steel coating quality and thickness or gauge, a 26-gauge (good), 24-gauge (better), or 22-gauge (best) Galvalume coated steel would be a better and a longer-lasting option compared to G-90 galvanized steel, especially in the heavy salt-spray, marine environments.

For most other environments, G-90 galvanized steel panels will work just fine. Be sure to look for Kynar 500 paint finish, whether you go with Galvalume or galvanized steel panels.

Total Cost per Square Foot Installed

A qualified contractor will likely have real metal samples, a brochure or catalog to show off all the possibilities in terms of colors and profiles, as well as any available custom colors or metal alloys like aluminum and zinc. They’ll provide all the information that backs up their work.

Therefore, if going with the national average, their prices will normally fall in the range of $12.50 to $20.50 per square foot to install standing seam metal roof on a typical house.

Metal

Flat

$15,500

$11,500

How to Find a Trusted Metal Roofer

Depending on your location, it can be tough to find a specialist roofing contractor that installs Standing Seam, but even more challenging is finding a pro that does it well.

Installation costs do take into account a number of factors, such as: how exactly will the panels be connected, what are some of the existing roof needs to address (i.e. attic insulation and ventilation, the tear off and disposal of the old roof, etc.), what are the options in terms of metals/alloys, colors and gauge or thickness of the material, whether the installer is properly insured, and whether or not any meaningful labor warranties are being offered.

Understanding Your Options

Unlike metal shingles, standing seam roofs make no attempt to mimic the appearance of other roofing options.

Did you know? Standing Seam is a unique roofing style in its own right. To some, it can appear rather plain, with its sleek vertical seams and simple panels that go from the roof ridge line the eaves.

It’s really a well-orchestrated roofing system. And given that color options are virtually unlimited, the beauty of standing seam is certainly in the eye of the beholder.

Stylistic Considerations and Suitability for Homes

Country and Contemporary homes are ideal choices for Standing Seam.

The most important aspect of style of a standing seam roof is in the name, the way it handles seams. Except for monolithic roofs, usually found on structures or homes with a flat top, almost all roofs will have some sort of seams.

With standing seam, the seams are raised. – The raised seams are where the sheet metal panels overlap one another side by side via a locking mechanism called the seam, without exposing any fasteners. — This method of connecting the metal panels side-by-side through a locking mechanism, minimizes chances of a future roof leak. Well, that’s the hope at least.

Over time, all roofs eventually fail due to age (or simply get replaced because of age and/or fading colors), but it’s far more likely that some other part of the roof or one of its features like chimney or skylights fail before a well-installed standing seam metal roof develops any leaks due to a failure of raised seams.

The good news is that a quality, professional metal roofing installer can delay that process with proper installation. And a wise homeowner can also engage in occasional ongoing maintenance like repainting any peeling paint (which can sometimes happen to non-Kynar 500 paint finishes) and inspections to ensure the proper functioning of the roof for the length of the material/system.

A standing seam roof installed right will likely last for a very long time; 50+ years of service lifespan is well within reason, depending on the kind of metal panels used, roof flashing points, etc.

Why Standing Seam?

On most roofing systems, such as wood, or slate, or even corrugated metal panels, the seams are intentionally exposed, and so are the fasteners. With standing seam, the fasteners are intentionally hidden, capped, and concealed by the overlapping metal panels, thanks to the raised seams that join the two adjacent panels together.

The vertical (standing) seams are the capped ridges between the panels — these locked seams give a standing seam metal roof its characteristic appearance. The raised seams are usually between half an inch to one and a half inches high.

Field or Mechanically Locked Standing Seam vs. Snap-Locked

Seams and panels can be snap-locked together, whereby the two adjacent sheet metal panels are joined and locked together at the seams — The snapping and locking action of the two panels is referred to as snap-locked. This method requires fewer tools and is easier to install, but the snapped lock is not nearly as reliable as the other method.

Snap-lock standing seam roofs installed right will provide 50 years of service lifespan. The overall quality of installation is always the key to a reliable and long-lasting metal roof.

Field-locked Standing Seam is a more popular method and requires special locking tool to join the panels together. Field-locking of the seams properly requires a certain level of skill and experience and knowing where to situate yourself during the installation, such that your body is not creating useless impact on the panels. The seams and panels are all metal, though the material is regularly chosen based on how the panels will appear.

Did you know? Copper and Zinc are also possible choices for standing seam. These are more expensive metals (especially copper), than steel or aluminum, but can be a viable option for some projects where the beauty of copper or durability of zinc are desired.

Steel and aluminum are the two main options for metal in the residential standing seam market. Both of these metals will naturally corrode over time, which is why we can thank the industry innovations for metallic coatings and high performance protective paint finishes.

It used to be that tin, which is highly resistant to corroding, was plated onto steel, as the primary metallic coating. But there are several reasons why “tin roofs” are a thing of the past. Nowadays, G-90 galvanized steel, Galvalume steel, aluminum, and in some case patinated zinc are the norm.

Galvanized means steel plated with a layer of zinc, which is a self-healing noncorrosive metal providing a layer of protection from oxidation including minor cuts to steel.

Galvalume refers to steel plated with an aluminum and zinc mixture (considered even less corrosive than G-90 galvanized steel)

Steel roofs must be coated first with a metallic finish to ensure they hold a coat of paint. Aluminum doesn’t necessity need such a coating, as it can be installed in mill finish, however most aluminum roofs are also painted, because people like the colors available with metal roofing.

How the materials are coated with paint will determine their lifespan. Factory finished with what is known as Kynar 500 or Hylar 5000 paint finish quality is arguably the best way to go. It’s actually less expensive than painting after the installation, since it’s just another run of the metal through the mill, not requiring man hours.

Width of panels is another consideration, though the standard range is between a foot and 19 inches.

Gauge is perhaps the last option, dealing with thickness of the metal panel. 29 gauge G-60 galvanized steel is the thinnest and least costly option in which metal panels are available.

G-60 galvanized steel panels (typically used on sheds) are typically finished with lower-end polyester paint and won’t last nearly as long as G-90 galvanized steel panels finished with Kynar 500 paint.

The lower the gauge of steel the thicker the metal. For example, gauge 22 steel would be the thickest panel option. For residential applications, the standard is 26- and 24-gauge steel.

Two Key Facts: The lower the gauge number, the thicker and sturdier, and hence more durable the metal panels are. Secondly, thickness of the metal doesn’t affect the price too much, but obviously can impact the overall durability and longevity of the roof.

Metal

Flat

$15,500

$11,500

Advantages

- Standing seam metal roofs are neatly suitable for residential and commercial PV solar panels installations, thanks to the raised seams that can be used as anchoring points, with no need to drill any holes in the roof.

- Raised seams are not exposed, which means there is far less of a chance the roof deck will be exposed to moisture and leaks.

- ROI or Cost-to-value is excellent for metal roofs, with homeowners recouping anywhere from 70% to 87% of money spent on a new standing seam metal roof at resale. This number can sometimes go as high as 95% on the right house and value-priced roof on the east coast of the U.S.

- Wide range of standard and custom color options

- Metal, if/when properly installed and maintained, will last for at least 50 years in most climates. 75-100 years or longer lifespan is very realistic with zinc and copper standing seam roofs.

- Metal is fire resistant, mildew resistant and insect/animals are not going to feed off it, or build their home in it.

- Metal holds up to wind and hail very well, though check with the specific system manufacturer to get precise info on this (where gauge or metal panel thickness matters).

- Metal roofs are green, Eco-friendly; they can reflect solar heat and make the home much cooler than other roof types.

- Metal is 100% recyclable, which is something that most other roofing materials cannot claim.

Disadvantages

- The upfront cost is often on the high-end for all types of residential metals roofs. Standing seam is far costlier than a conventional roofing system like asphalt shingles. However, standing seam offers far greater value and will last two to three times longer than a typical asphalt roof.

- Oil canning can sometimes be an issue with standing seam panels, especially if panel length and width is greater than average. Oil canning can be prevented with a mid-panel rib stiffening method, which should be done prior to installation.

- Unlike asphalt shingles that most conventional roofers can easily install, standing seam is a specialty roofing system that requires appropriate training, experience, and special tools to install. It’s more difficult to install than most other roofing systems, especially on roofs with multiple dormers and valleys, skylights, chimneys, end-walls, and other roof flashing points.

- Some areas may have limited availability of trained crews that install standing seam on a regular basis.

- Improper installations can be very difficult and costly to repair, sometimes requiring a complete do-over.

- Ongoing maintenance may occasionally be needed — while metal roofs last for a very long time with very little maintenance relative to other roofing materials, standing seam paint finish may sometimes be an issue, especially with low-end paint finishes like Polyester. Residential grade standing seam panels featuring Kynar 500 paint finish or equivalent should offer 30 years (warrantied) of lasting performance for the paint finish alone before the metal is even exposed to the elements.

- While standing seam panels are very durable when installed properly, in rare cases, they can dent with enough force like very large hail stones, person walking on it in haphazard way and stepping directly onto the raised seams, or large nearby branches falling with great force on it.

Need a Pro? Check out Prices from Local Roofers:

Enter your zip code:

See what local pros charge

See what local pros charge